Field installation

Field realization

Design of Kits

> Design and realization of a "POWER" 120 KVA KIT for emergency compound.

January 2014

Following a tender initiated by MERLIN and won by the end of 2013, in 3 months we prepare a compound electrification kit, to be deployed in an emergency and transferred back afterwards if needed.

The design in itself was a joined project with the NGO's engineer ; from the city mains supply to the lighting of each space.

A global "distribution board" allows the selection between the various supplies, with clear visualization of those which are live. We use a 100 Kva source selector. Two 60 Kva trailer-mounted WILSON generators are also connected, pre-wired, with maintenance kit and proper grounding.

Three smaller switchboards allow to power the three clearly defined compound ZONES. The connection cables have a standard lenght (25m/10m/5m), for an easy installation according to the distances to be met on the field.

Each zone includes a pre-defined number of lighting points, outside (the walkways) and inside, in each room, latrine included.

SECURITY is not forgotten : every distribution panel is electrically grounded and features an electric differntial.

The whole is completely "PLUG AND PLAY" to allow a quick and easy installation in an emergency - under stress - situation.

Next to the two 60KVA generators, all the equipment is stored in 79 chests / 100 L metal trunks with combination padlocks.

The trunks of each of the three zones have their unique colour : green / yellow / blue, to allow a quick management of the deployment amongst the three zones.

The equipment has been shipped to the U.K., to be stored in the emergency stock of the NGO, and to allow the training of the logistics team.

A partial deployment has been made, much to the satisfaction of the NGO.

A fine example of partnership, sharing the knowledge and the experience.

-----------------------------------------------------------------------------------------------------------------------------------

Design and installation of a 21Kw power system back up - Uganda - Mbarara - May 2011 -

Mbarara FRUKv1

Acting as our first power system installation in response to the following requirements:

Supply 27 KW for 30mins comming from a system capable of seamlessly switching between the city supply and emergency generators.

The customer request and field situation :

Epicentre (Paris) runs a medical research laboratory at M’barara, 4 hours from Kampala. The research is the field of DNA analysis and HIV epidemiology. Some of the analytical processes take many hours and cannot be interrupted once started. Due to the use if retrovirals the laboratory staff are protected by a negative pressure air filtration system that guarantees containment...Likewise it is out of the question that this system could be suddenly stopped while handling was in progress.

Some of these machines require a clean, stabilised voltage supply.

The city power supply is subject to numerous power outages and isn’t very satble. An emergengy generator takes over in such an eventuality - but the switchover takes several minutes, normally destroying any treatment processes in progress. To avoid this situation, EPICENTRE wanted to implement a professional and global solution for the whole laboratory.

Our solution :

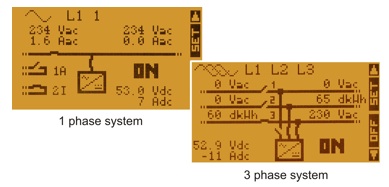

Is comprised of 9 STUDER Xtender 3500 units offering a continuous power of 3000 W running from 24Vdc batteries with a switchover time set at 15ms

The distribution of laboratory mains power is split into three groups of 9000W, each group made up of three Xtenders, giving the advantage of balancing the load across three separate phases. That is to say each group is an independant source of 230 Vac.

One “group” therefor consists of 3 Xtenders connected together. One of the three units controls the othe two according to demand. If one of the three units fails the other two take over if they are able to supply the power demand.

Tests of unexpected outages while the laboratory was running have confirmed the effectiveness of this system.

A remote control unit allows the monitoring and memorising of the parameters of each Xtender.

In close partnership with EPICENTRE, TSF Supply has developed the whole project from study and scaleing to planning and installation (which required one week)

Naturaly, training on the maintenance and use of the remote control has been provided.

Illustrations: The installation and, here above, the remote control display, to monitor and set various parameters.